About Fabrication

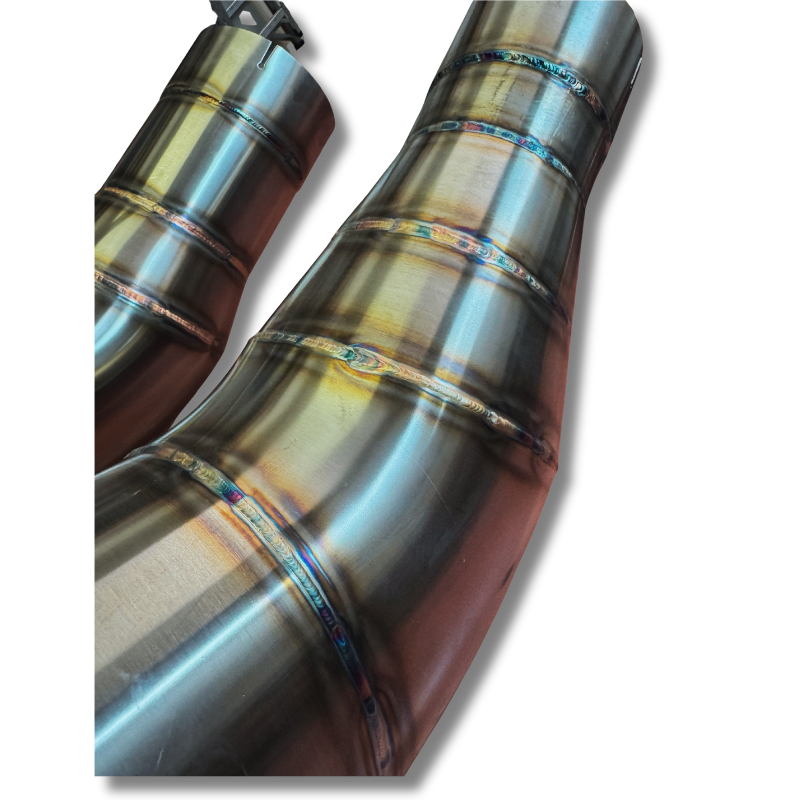

In‑house welding & custom exhaust systems

FAS Motorsports operates a full in‑house fabrication and welding department that designs, prototypes, and produces custom exhaust, catalyst, and piping systems for gasoline and diesel platforms. We handle one‑off projects, production runs, and motorsport‑grade assemblies with controlled QA.

Our approach

For forced‑induction and high‑RPM builds, we prioritize flow and thermal stability. Typical deliverables include cat‑back systems with optimized muffler cores, heat‑managed downpipes, and charge‑pipe routing that minimizes volume while maintaining laminar flow to the throttle body.

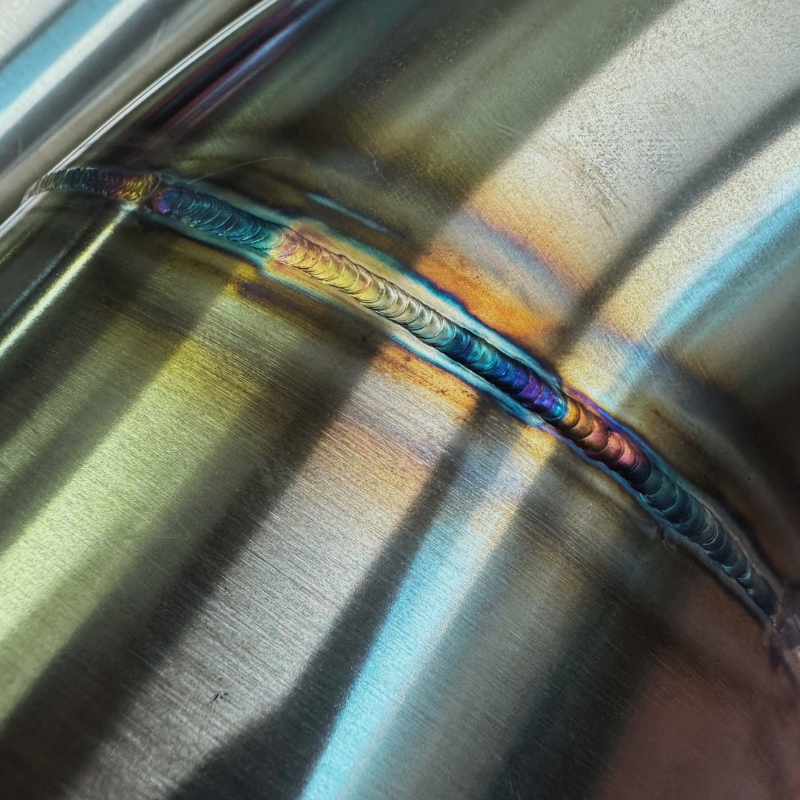

Diesel systems are engineered for continuous high EGT and vibration with reinforced hangers, expansion allowances, and optional resonators to control drone under load. All stainless assemblies are back‑purged TIG welded for interior smoothness and corrosion resistance, then leak‑checked and documented with torque specs.

At‑a‑glance

- Typical Lead Time

- 5–10 days

- Weld Method

- 100% TIG

- Material Options

- 304 / 316L

- Joint Types

- V‑band / Slip

F.a.S.MOTORSPORTS

PRECISION ENGINEERING • CUSTOM FABRICATION • PERFORMANCE TUNING